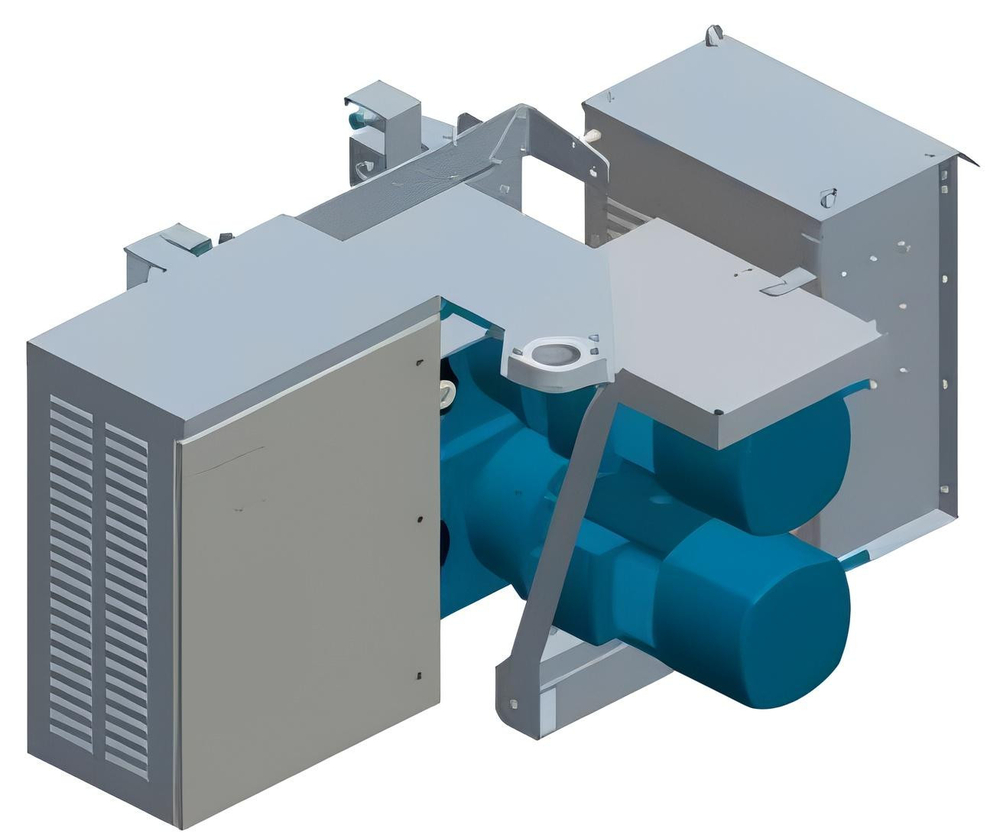

Spare Parts - For all brands of Man & Material Hoist ( MMH) - Drive Unit

Spare Parts - For all brands of Man & Material Hoist ( MMH) - Drive Unit Specification

- Hook

- Forged Steel Hook

- Surface Finish

- Anti-Corrosive Coating

- Frequency

- 50 Hz

- Lifting Speed

- 33 m/min

- Usage

- Industrial Construction Hoist Applications

- Power Source

- Electric

- Sling Type

- Steel Wire Rope

- Maximum Lifting Weight

- 1000 kg

- Maximum Lifting Height

- 100 meters

- Lift Speed

- 33 m/min

- Power

- 7.5 kW

- Voltage

- 415 V

- Rotating Speed

- 1440 RPM

- Insulation Grade

- F

- Trolley

- Compatible with all major MMH brands

- Capacity

- 1000 kg

- Motor Type

- Heavy Duty Induction Motor

- Material

- High-grade Alloy Steel and Durable Components

- Brake System

- Electromagnetic Fail Safe Brake

- Service Life

- Long-Life, Maintenance-Friendly Design

- Protection Class

- IP54

- Weight of Unit

- Approx. 120 kg

- Compatibility

- Suitable for all brands of man and material hoist MMH drive units

- Ambient Temperature Range

- -10°C to +50°C

- Noise Level

- <80 dB

- Control Method

- Push Button Pendant and Remote Control options

- Gear Box

- Helical or Planetary Gear Drive (as per model)

- Mounting Type

- Bolt-On/Replacement for Existing Hoists

About Spare Parts - For all brands of Man & Material Hoist ( MMH) - Drive Unit

With over 30 years of expertise, a 200+ strong team, and 300+ machines under AMC/PMC care, Mast Climber Private Limited is Indias trusted partner for hoist, MCWP, and RSP maintenance, installation, breakdown response, spare support, and technical upgrades.

Universal Compatibility Across MMH Brands

Our drive units are meticulously designed to seamlessly integrate with all leading brands of man and material hoist systems. Whether youre upgrading an older hoist or outfitting a new project, the bolt-on, replacement-ready units simplify installation and ensure a precise fit, reducing your downtime and operational complexity.

Engineered for Reliability and Safety

Safety and durability are at the forefront, with features such as an electromagnetic fail-safe brake, robust helical or planetary gear drives as per model, and anti-corrosive coatings. The combination of high-grade steel components and IP54-rated protection ensures these units withstand harsh construction environments and rigorous industrial usage.

Optimized Control and Performance

Experience flexibility with push button pendant and remote control operation, paired with a high-efficiency motor delivering 7.5 kW and 1440 RPM. The forged steel hook, sturdy trolley compatibility, and steel wire rope lifting components guarantee smooth, safe, and rapid lifting, meeting the dynamic needs of modern construction applications.

FAQs of Spare Parts - For all brands of Man & Material Hoist ( MMH) - Drive Unit:

Q: How do I ensure this drive unit is compatible with my existing man and material hoist?

A: Our drive units are universally designed to be compatible with all major MMH brands. The bolt-on mounting system allows straightforward replacement or upgrading of existing drive units without extensive modifications. For specific guidance, please consult our support team with your hoist model details.Q: What are the key benefits of using high-grade alloy steel and durable components in this drive unit?

A: Using high-grade alloy steel and robust components enhances the units durability, load-bearing capacity, and resistance to wear and corrosion. This results in a longer service life, decreased maintenance frequency, and reliable operation under demanding industrial conditions.Q: When should the electromagnetic fail-safe brake be serviced?

A: It is advised to inspect and service the electromagnetic fail-safe brake at regular maintenance intervals specified in your hoists manual, or if you notice delayed stopping or unusual noises. Routine maintenance ensures optimal safety and system responsiveness.Q: Where can these drive units be used?

A: These units are specifically designed for industrial construction hoist applications across various sectors. Suitable for both indoor and outdoor use, their IP54 rating and anti-corrosive coating make them ideal for harsh environments encountered on construction sites across India.Q: What is the process for replacing an existing drive unit with this product?

A: Replacing your drive unit involves disconnecting the power supply, removing the old unit, and securing the new drive unit using the bolt-on system. Once mounted, electrical connections are made following the manufacturers wiring diagram, after which operational checks and safety tests must be carried out before use.Q: How does the remote control or push button pendant improve hoist operation?

A: The remote control and push button pendant options give operators flexibility and enhanced safety, permitting precise and convenient control over lifting operations from a safe distance, thus reducing the risk of accidents and streamlining workflow.Q: What makes this drive unit suitable for heavy-duty and long-life service?

A: The combination of a heavy-duty induction motor, precision gear drive (helical or planetary), electromagnetic safety brakes, and high-quality chassis ensures continuous operation with minimal downtime. Maintenance-friendly design and durable materials further extend the service life.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Passenger Cum Material Hoist/Lift Category

Rack and Pinion Passenger and Material Hoist

Price 6000000 INR / Unit

Minimum Order Quantity : 1 Unit

Lift Speed : 90 mm/m

Capacity : 25 persons /2,000 kg to 30 persons /3,200 kg Kg

Maximum Lifting Height : 400 Meter (m)

Surface Finish : Hot Dip Galvanised

Spare Parts - For all brands of Man & Material Hoist ( MMH)- Complete Pull Rod

Price 1 INR / Number

Minimum Order Quantity : 2

Lift Speed : Depends on application

Capacity : Suitable for rated hoist load

Maximum Lifting Height : As per hoist specification

Surface Finish : Corrosion resistant, powder coated/galvanized

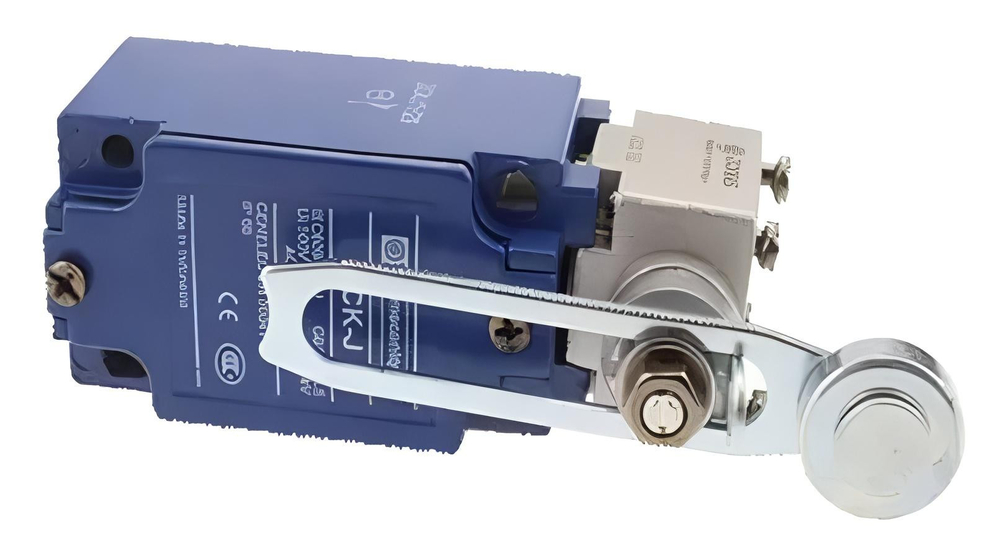

Spare Parts - For all brands of Man & Material Hoist ( MMH) - Limit Switch

Price 1 INR / Number

Minimum Order Quantity : 2

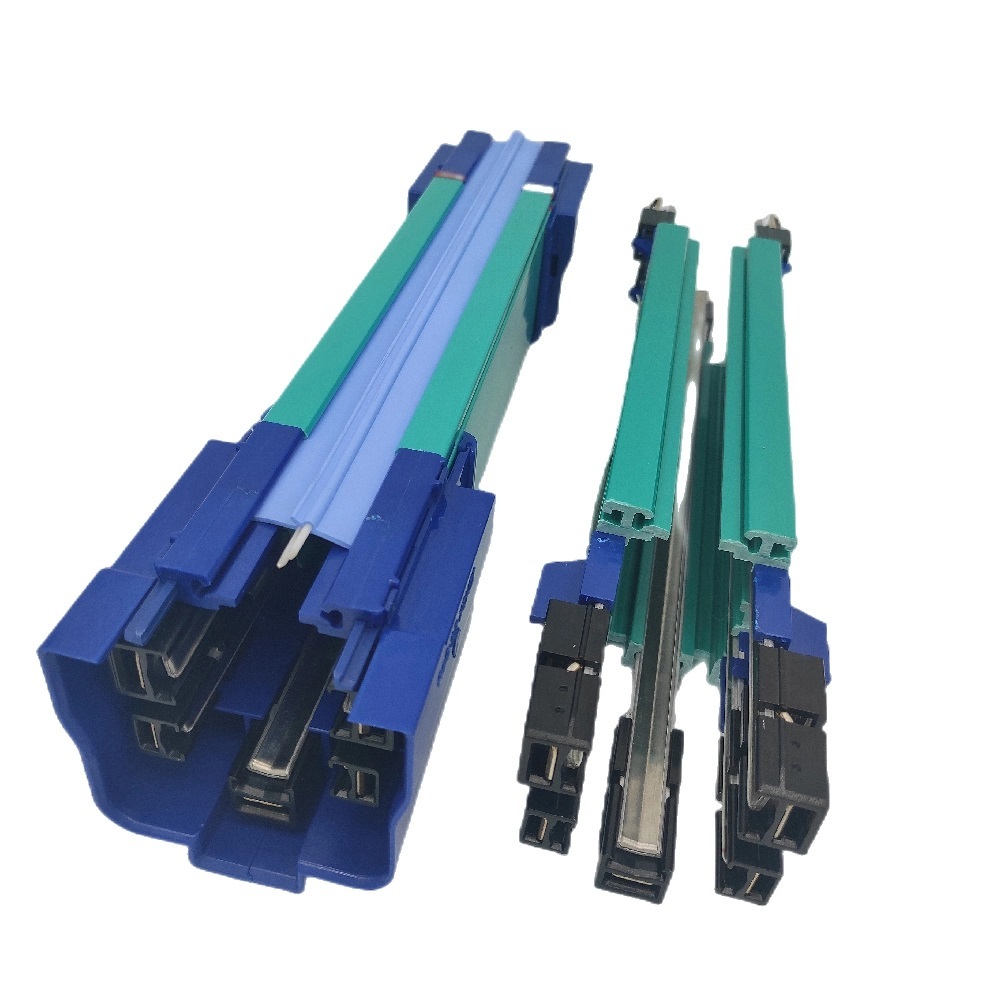

Spare Parts - For all brands of Man & Material Hoist ( MMH) - Busbar System

Price 1 INR / Number

Minimum Order Quantity : 2

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese