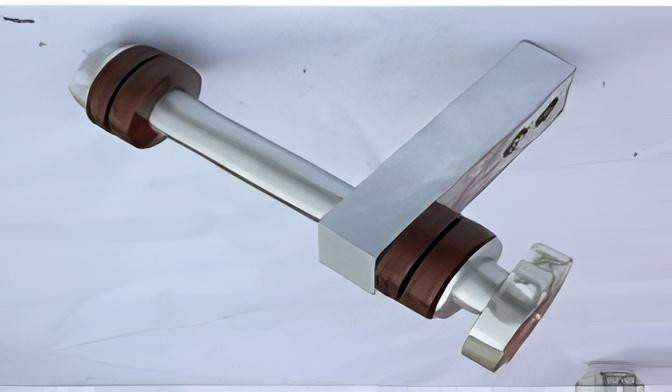

Spare Parts - For all brands of Man & Material Hoist ( MMH)- Complete Pull Rod

Spare Parts - For all brands of Man & Material Hoist ( MMH)- Complete Pull Rod Specification

- Hook

- Not Applicable (Used as Pull Rod for Hoists)

- Surface Finish

- Corrosion resistant, powder coated/galvanized

- Frequency

- 50/60 Hz

- Usage

- Replacement part for Man & Material Hoist

- Maximum Lifting Weight

- As per hoist capacity

- Maximum Lifting Height

- As per hoist specification

- Lift Speed

- Depends on application

- Trolley

- Compatible with single/double cage MMH

- Capacity

- Suitable for rated hoist load

- Part Type

- Complete Pull Rod Assembly

- Application

- Industrial construction hoisting; elevating men/materials

- Corrosion Resistance

- Yes; suitable for outdoor/construction usage

- Manufacturing Standard

- Conforms to ISO/CE hoist parts standards

- Compatibility

- Universal; fits all major MMH brands

- Dimensions

- Customized as per hoist make/model

- Shape

- Precision machined rod as per OEM design

- Material Composition

- Alloy steel / high tensile steel

- Installation

- Direct fit; easy alignment design

- Weight

- Varies based on model

About Spare Parts - For all brands of Man & Material Hoist ( MMH)- Complete Pull Rod

With over 30 years of expertise, a 200+ strong team, and 300+ machines under AMC/PMC care, Mast Climber Private Limited is Indias trusted partner for hoist, MCWP, and RSP maintenance, installation, breakdown response, spare support, and technical upgrades.

We offer a wide range of spare parts, including Mast sections, Ties, Rollers, Pinions, Limit Switches, Cables, Cable Trolleys, Safety Devices, Veichi Control Panels, Load Cells, Gearbox Motors, Liners, Electromagnetic Brakes, and more.

Precision Engineering for Safety and Performance

Each pull rod is manufactured with meticulously selected alloy or high tensile steel, guaranteeing exceptional strength and reliability. The precision machining process replicates the original equipment manufacturers (OEM) design, allowing for accurate alignment and a perfect fit within your hoist system. Surface finishes are engineered for maximum corrosion resistance, making these rods suitable for the rigors of construction and industrial usage.

Universal Compatibility and Standard Compliance

Our complete pull rod assemblies were developed for broad compatibility, fitting all major brands and models of Man & Material Hoists (MMH). Every unit adheres strictly to ISO and CE hoist part standards, ensuring quality and safety across various hoisting applications. Trolley compatibility spans both single and double cage MMH types, enhancing their usability on diverse project sites.

FAQs of Spare Parts - For all brands of Man & Material Hoist ( MMH)- Complete Pull Rod:

Q: How is the complete pull rod assembly installed in Man & Material Hoists (MMH)?

A: The pull rod assembly features a direct-fit, precision-machined design, allowing for straightforward installation. It is engineered for easy alignment, seamlessly integrating with your MMHs existing setup, usually without the need for additional modifications or adjustments.Q: What materials are used in the manufacturing of the pull rod assembly?

A: The pull rods are crafted from high-grade alloy steel or high tensile steel, selected for their superior strength, durability, and resistance to wear. These materials also ensure long-term performance even in demanding outdoor and industrial conditions.Q: When should I consider replacing the pull rod in my hoist system?

A: Replacement is recommended when the original pull rod shows signs of excessive wear, corrosion, bending, or fatigue. Regular inspection as part of routine hoist maintenance can help identify these issues before they compromise safety or performance.Q: Where can these pull rods be used, and are they suitable for all MMH types?

A: These pull rod assemblies are designed for universal compatibility with all major MMH brands and models, including both single and double cage hoists. They are ideal for use in construction, industrial hoisting, and anywhere reliable elevation of personnel and materials is required.Q: What is the process for customizing the pull rod dimensions to specific hoist models?

A: To customize the pull rod, users provide the make and model specifications of their hoist. The assembly is then manufactured to precise OEM dimensions, ensuring perfect fit and alignment with the required hoist application.Q: How do these pull rods benefit users in harsh environments?

A: With corrosion-resistant powder coated or galvanized surfaces, the rods withstand exposure to humidity, rain, and construction debris. This extends the service life of the hoist and maintains reliable operation in outdoor and rugged jobsite conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Passenger Cum Material Hoist/Lift Category

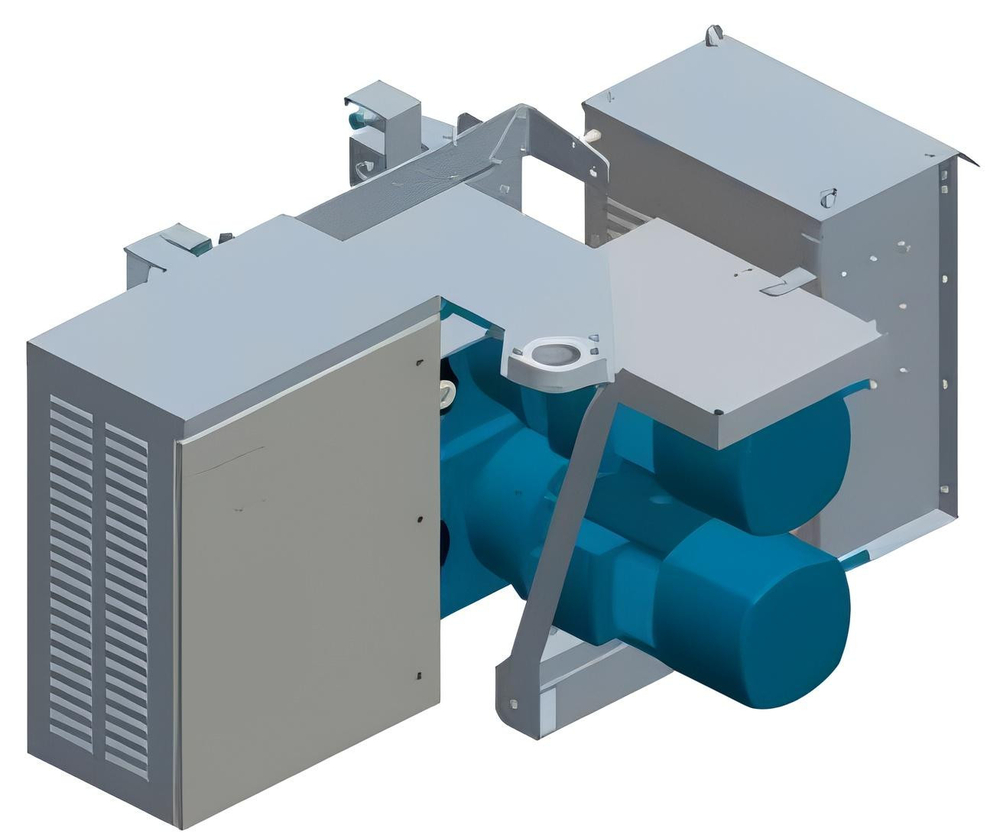

Spare Parts - For all brands of Man & Material Hoist ( MMH) - Drive Unit

Minimum Order Quantity : 0 to 100 Number

Usage : Industrial Construction Hoist Applications

Maximum Lifting Height : 100 meters

Voltage : 415 V

Maximum Lifting Weight : 1000 kg

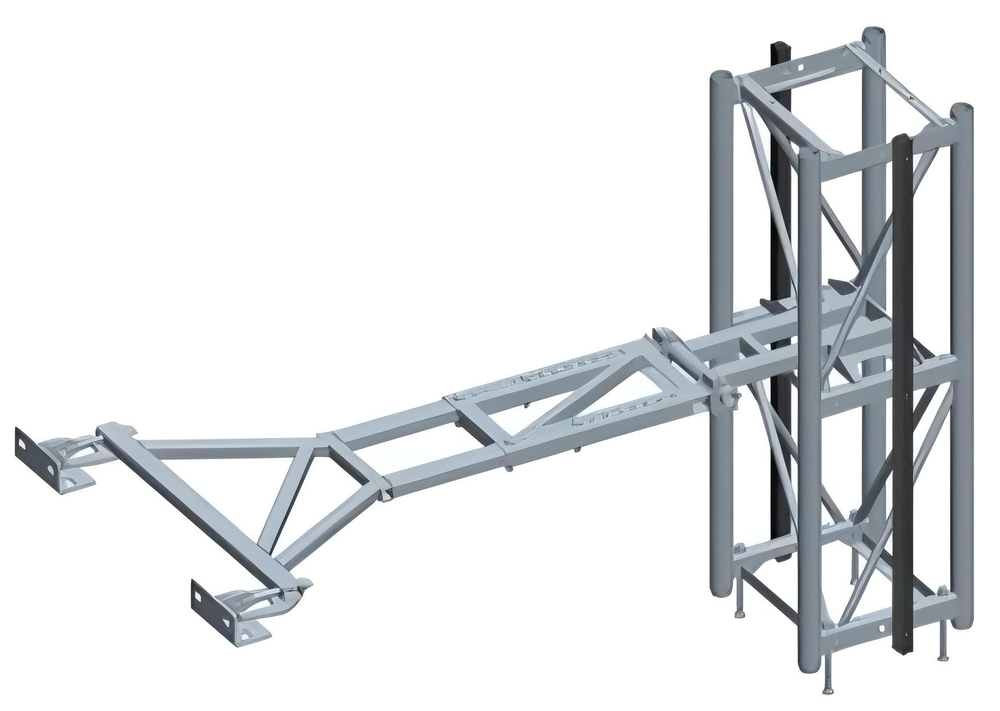

Spare Parts - For all brands of Man & Material Hoist ( MMH) - Mast Ties

Minimum Order Quantity : 0 to 100 Number

Usage : Support and stabilize mast structure in man & material hoists

Maximum Lifting Height : As per hoist design (mastdependent)

Voltage : 380V/415V or as per hoist system

Maximum Lifting Weight : As per hoist model

Spare Parts - For all brands of Man & Material Hoist ( MMH)- Contrast Roller

Price 1 INR / Number

Minimum Order Quantity : 2

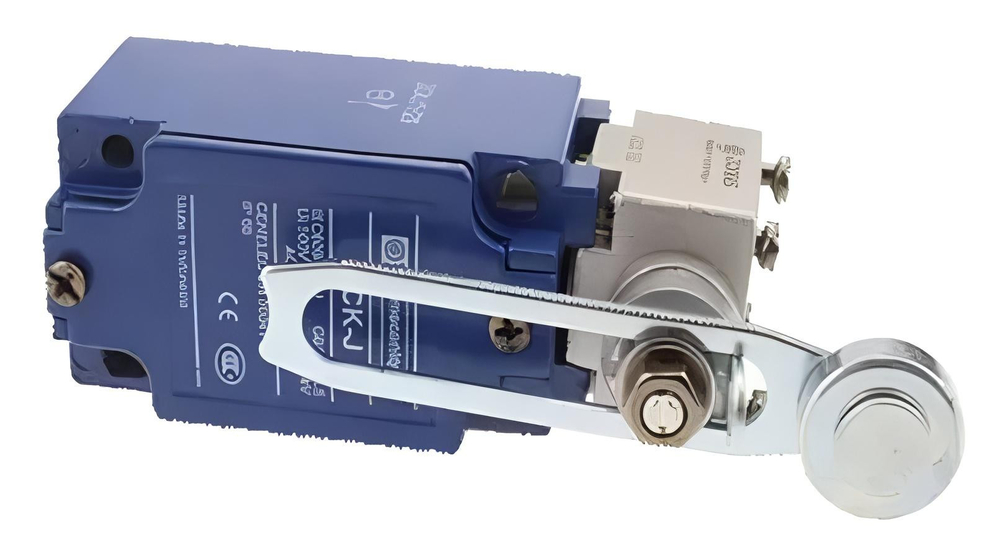

Spare Parts - For all brands of Man & Material Hoist ( MMH) - Limit Switch

Price 1 INR / Number

Minimum Order Quantity : 2

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese