Spare Parts - For all brands of Man & Material Hoist ( MMH)- Joystick

Spare Parts - For all brands of Man & Material Hoist ( MMH)- Joystick Specification

- Lifting Speed

- Customizable as per hoist model

- Frequency

- 50/60 Hz

- Hook

- Compatible with standard and heavy-duty hooks

- Surface Finish

- Corrosion-resistant, industrial grade

- Usage

- Spare part for Man & Material Hoist (MMH)

- Power Source

- Electric

- Sling Type

- Wire rope/chain as per hoist model

- Maximum Lifting Weight

- Matches original hoist design specification

- Maximum Lifting Height

- Defined by hoist and operational requirement

- Lift Speed

- Adjustable via joystick control

- Power

- Compatible with corresponding hoist power supply

- Voltage

- 110V/220V/380V options

- Rotating Speed

- Precision control based on application

- Insulation Grade

- Class F or equivalent

- Trolley

- Suitable for manual and motorized trolleys

- Capacity

- Supports various load capacities as per hoist rating

- Color

- Standard black handle with colored switch caps

- Contact Configuration

- NO/NC contact blocks

- Compatibility

- Suitable for all major brands of Man & Material Hoist

- Cable Entry

- Standard grommet with support for flexible cables

- Enclosure Rating

- IP54/IP65 depending on model

- Weight

- Approx. 350 grams (may vary by model)

- Control Type

- Multi-directional joystick

- Application

- Control of lifting/lowering and trolley movement in MMHs

- Mechanical Life

- Over 1 million operations

- Operating Temperature Range

- -20°C to +55°C

- Maintenance

- Low maintenance, easy replacement design

- Mounting Type

- Panel mount / remote mount options

- Safety Features

- Fail-safe spring return, ergonomic grip

- Material

- High-strength ABS/Polycarbonate

About Spare Parts - For all brands of Man & Material Hoist ( MMH)- Joystick

With over 30 years of expertise, a 200+ strong team, and 300+ machines under AMC/PMC care, Mast Climber Private Limited is Indias trusted partner for hoist, MCWP, and RSP maintenance, installation, breakdown response, spare support, and technical upgrades.

We offer a wide range of spare parts, including Mast sections, Ties, Rollers, Pinions, Limit Switches, Cables, Cable Trolleys, Safety Devices, Veichi Control Panels, Load Cells, Gearbox Motors, Liners, Electromagnetic Brakes, and more.

Universal Compatibility for Man & Material Hoists

Our multi-directional joysticks are engineered to suit all major brands of Man & Material Hoist (MMH), ensuring seamless integration across diverse operational setups. Whether for manual or motorized trolleys, standard or heavy-duty hooks, these joysticks provide comprehensive compatibility, making them ideal replacement solutions for a wide variety of industrial hoist applications.

Durable Construction and Superior Safety

Built with high-strength ABS/polycarbonate, our joysticks are tested for over one million mechanical operations, offering low maintenance and high reliability. Safety is reinforced with a fail-safe spring return and ergonomic design, making these control units both robust and user-friendly, suitable for demanding industrial environments and frequent usage.

Customizable and Easy to Install

Offering panel and remote mounting options, the joysticks are supplied with standard grommets for flexible cable entry, and support NO/NC contact configurations. Operating within a temperature range of -20C to +55C, the replacement process is efficient, ensuring minimal downtime. Customize lifting speed and controls according to hoist specifications for optimal performance.

FAQs of Spare Parts - For all brands of Man & Material Hoist ( MMH)- Joystick:

Q: How do I know if this joystick is compatible with my Man & Material Hoist brand?

A: Our multi-directional joystick spare part is universally designed to fit all major Man & Material Hoist brands. It supports both manual and motorized trolleys, standard and heavy-duty hooks, and meets various load capacities and voltage requirements. Check your hoists technical specifications for required voltage and mounting type to ensure proper compatibility.Q: What is the process of installing the joystick spare part?

A: The joystick can be panel-mounted or remotely installed depending on your system layout. Its design incorporates standard cable entry and support for flexible cables, making wiring straightforward. Detailed installation guides are provided, and no specialized tools are required for replacement or initial mounting. Always ensure appropriate power isolation before installation.Q: Where can this joystick be used, and what are its main applications?

A: This joystick is crafted as a spare part for Man & Material Hoists used in industrial, construction, and material-handling environments. It controls lifting, lowering, and horizontal movement of the trolley across various MMHs, making it integral for safe and precise operations in warehouses, construction sites, and manufacturing plants.Q: What are the key benefits of this replacement joystick?

A: Key benefits include high mechanical life (over one million operations), fail-safe spring return, ergonomic grip for user comfort, corrosion-resistant finish, and low maintenance. Its wide compatibility and easy-to-replace design minimize downtime and maximize operational efficiency.Q: When should I consider replacing the joystick on my hoist system?

A: Replace the joystick if you notice unresponsive controls, inconsistent movements, visible wear, or damage. Routine maintenance checks can help identify wear and tear early, ensuring continued safety and optimal performance. Replacement is also recommended if upgrading to enhanced safety or IP-rated models.Q: What maintenance does this joystick require?

A: The joystick features a low-maintenance design with high-strength materials and industrial-grade finishes. Periodic inspection for dust, moisture ingress, or physical damage is recommended. Cleaning with a dry cloth and checking for secure connections will help maintain optimal operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Passenger Cum Material Hoist/Lift Category

Spare Parts - For all brands of Man & Material Hoist ( MMH) -Brake electromagnet

Price 000001 INR / Number

Minimum Order Quantity : 0 to 100 Number

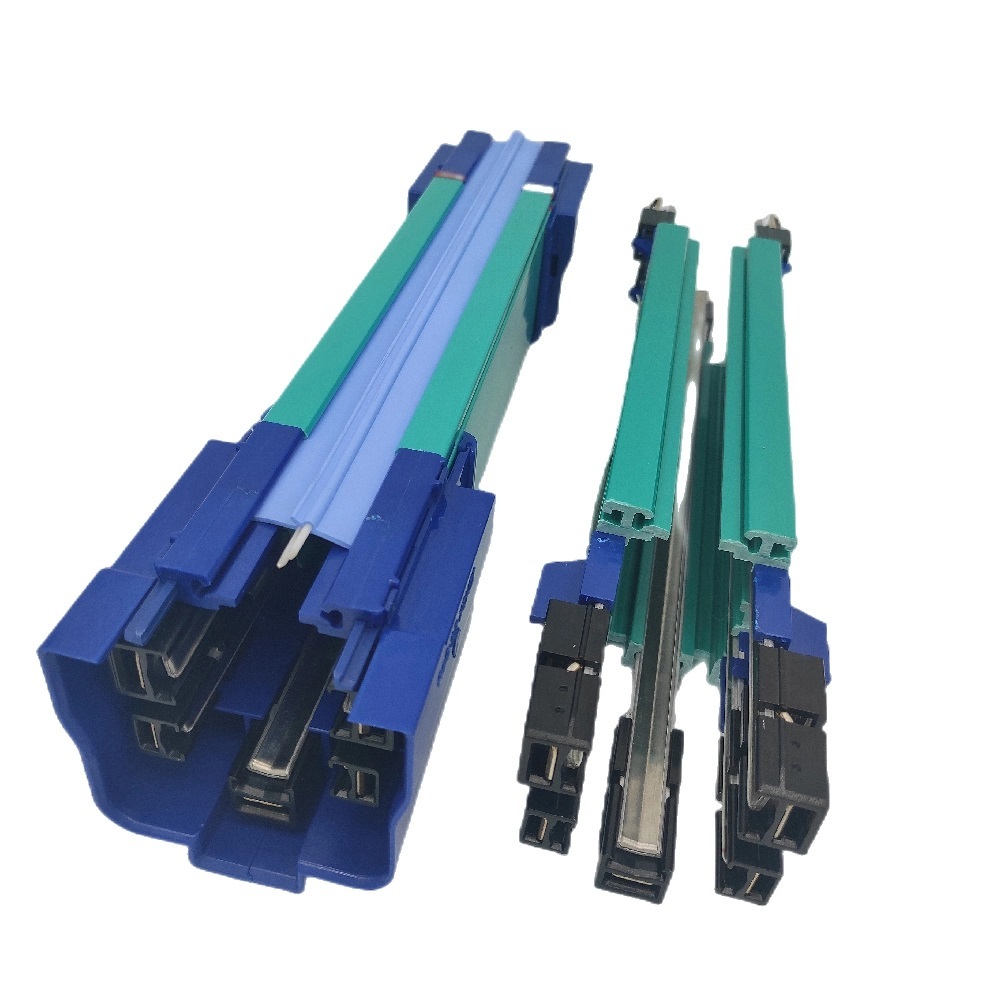

Spare Parts - For all brands of Man & Material Hoist ( MMH) - Busbar System

Price 1 INR / Number

Minimum Order Quantity : 2

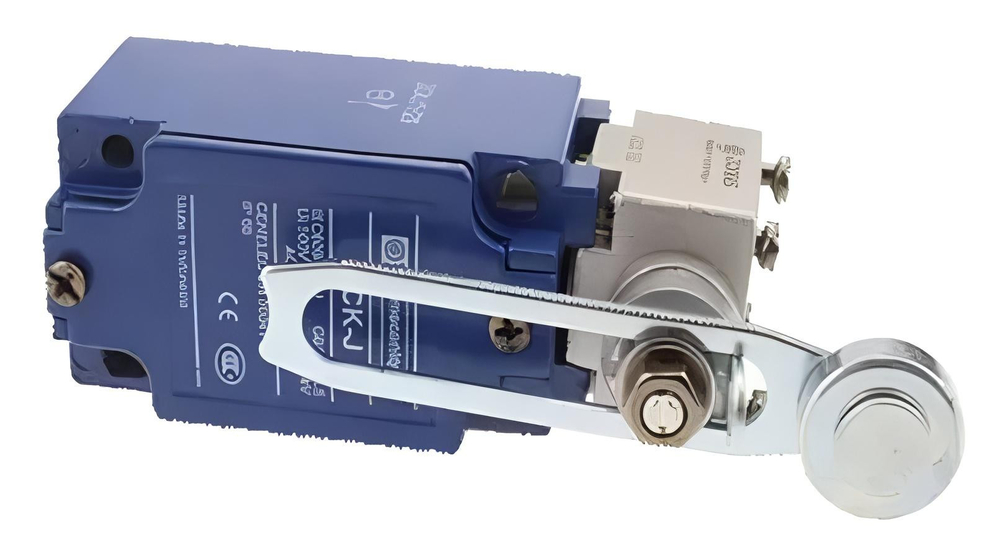

Spare Parts - For all brands of Man & Material Hoist ( MMH) - Limit Switch

Price 1 INR / Number

Minimum Order Quantity : 2

Spare Parts - For all brands of Man & Material Hoist ( MMH)- Support Roller Assembly

Price 1 INR / Number

Minimum Order Quantity : 2

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese